Portable Liquid Cylinders

The foundation of CHART products with superior performance is innovation, including the lowest product life cycle cost, safety, and ease of use. Determination of quality, precise craftsmanship and superb technology are included in developing and manufacturing every world-class liquid cylinders.

1. Large Diameter Handling Ring with Four Supports

If you cut corners here, the pipes, instruments, and valves on the top of the bottle may be damaged during transportation. Therefore, CHART uses a bracelet with a diameter of 33mm and channel steel as a pillar to increase its strength.

2. Neck Tube

This area is the weakest when the cylinder is tipped over. So CHART uses a tough neck tube to withstand the impact, but at the same time to help reduce thermal conductivity.

3. Support Ring

You can’t see it because it’s welded on the inside of the bladder. But in the unfortunate event of a cylinder being dropped or tipped over, you can take comfort in the fact that it is there to protect the cylinder and the product inside.

4. Outer-Vessel

CHART’s high-strength stainless steel casings have always been the best in the industry. In line with the service spirit of excellence, the stainless steel casings of CHART have been further strengthened with quality assurance.

5. Insulation Materials

CHART is processed in the gap between the inner and outer containers with an exclusive multi-layer winding thermal insulation process. You can see its efficiency from our Normal Evaporation Rate (NER), and CHART’s entire line of cylinders has the lowest NER.

6. Inner-Vessel

CHART’s all-stainless steel liner is strictly implemented under DOT 4L/TC4LM specifications in design, construction, production, and inspection.

7. Evaporator

Time is money, and when you need gas, you always want it to be available immediately. Therefore, we use a long copper tube 100% welded on the inner side of the outer tank to achieve the highest heat conduction efficiency, and the automatic supercharger can maintain the gas flow. CHART’s gas cylinders have the highest gas discharge rates.

8. Bottom support

The tension applied to the inner container is considerable in the event of a fall or tipping over. Of course, you shouldn’t allow this to happen, so a bottom support that can take this shock is important.

9. Footring

No one knows the actual use of gas cylinders better than us. You will find that cylinders are subject to rough handling, wear and tear, bumps, and falls while transported. CHART’s well-designed all-stainless steel footing is flexible enough to absorb impacts and rigid enough to prevent slamming.

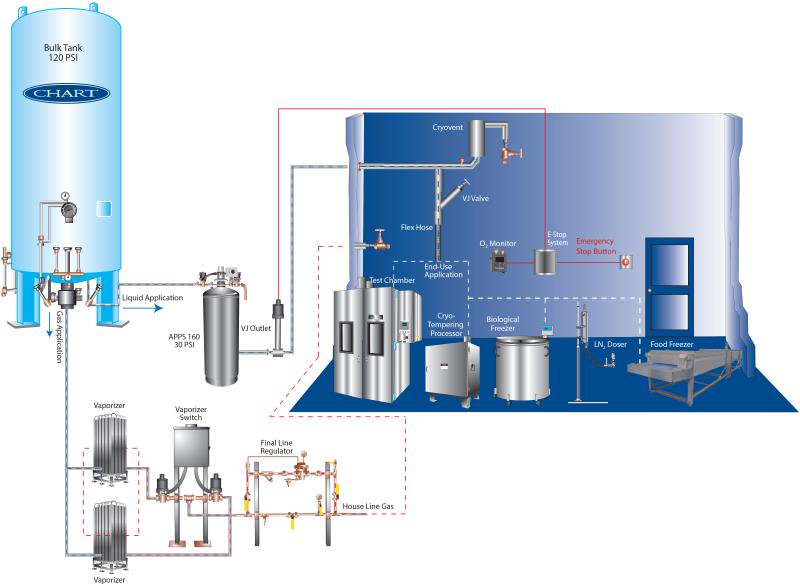

Cryogenic Storage Tank

CHART new generation of large cryogenic storage tanks is even better

CHART Corporation has been a recognized leader in manufacturing sizeable cryogenic storage tanks for three decades. The latest research has produced the VS series of cryogenic storage tanks that store liquid nitrogen, oxygen, or argon. Another type of CHART tank can also store liquid hydrogen and carbon dioxide.

CHART’s equipment meets or exceeds the required design specifications of low-temperature pressure vessels, and the VS-type storage tanks manufactured by CHART can implement the credit guarantee of CHART – using high-quality materials and accessories and superior manufacturing technology.

The Latest Insulation Technology

CHART continues to develop thermal insulation systems and has finally created new high-performance thermal insulation materials. This newest insulation material is X-Cel composite, the lightest body, the best insulation system for maximum efficiency in normal vacuum conditions, and easy maintenance.

Simplified Design

The design of this VCS-type storage tank minimizes the number of pipes and components, thus reducing the possibility of gas leakage or component failure, making maintenance more convenient and reducing costs.

Extend Storage Time

The new generation of sizeable cryogenic storage tanks adopts CHART’s X-Cel composite high-efficiency thermal insulation system to improve storage time. This storage tank is designed with a pressure of 175psig (1.2MPa) compared to the traditional 250psig (1.73MPa) pearlescent Sand insulated storage tanks have a longer shelf life. You can reduce costs by choosing the right tank pressure for your specific application.

Vaporizer

With a unique design and high thermal conductivity of aluminum alloy, the vaporizer uses the surrounding atmospheric heat to vaporize the cryogenic liquid into gas. It can work under pressure up to 41.4bar, and the flow rate is available from 6.6 to 131.4Nm3/hour.

Flow rates are calculated with the continuous use of nitrogen at an atmospheric temperature of 21°C*. The peak traffic can be increased to four times the regular traffic in 15 minutes. The design of the pipe assembly in the installation allows either end of the two ends to be used as an outlet or an inlet.

* Assuming an environment with a relative humidity of 70% and an altitude of 1524 meters

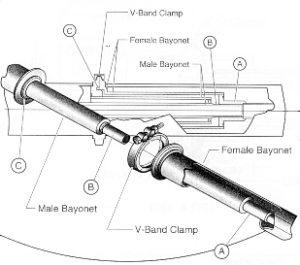

VIP Vacuum Insulation Pipe

Chart Industries is the world’s leading designer, manufacturer, and installer of technology and Modular Vacuum Insulated Pipe (MVIP) systems.

Vacuum Insulated Tubing may also be called Vacuum Shelter Mode Tubing, Cryogenic Tubing, or Super Insulated Vacuum Line (SIVL).

Covers a wide range of traditional industrial applications, including leaky heat-sensing helium lines to highly engineered aerospace applications.

Simple: Simple installation using standard modules and quick bayonet connections.

Reliable: Long-term reliability, providing many years of maintenance-free service.

High performance: The thermal efficiency is more than 10 times that of the foam insulation pipe.

Leave A Comment